Induction Power Generator

The Induction Power Generator usually referred as Induction Heating Power Supply or Induction Invertor. Widely used for metal hardening, annealing, welding, forging, melting, brazing, pre-heating etc. It offfers precise, efficient, fast heating method.

Features

● Fast heating ● Efficient ● Precise

With the coming age of highly engineered materials, alternative energies and the need for empowering developing countries, the unique capabilities of induction offer engineers and designers of the future a fast, efficient, and precise method of heating.

As the technology of choice for rqpid, clean heating that is repeatable, accurate, and efficient, induction technology has established itself firmly in the future of manufacturing as a cornerstone of the industry.

Induction power inverter

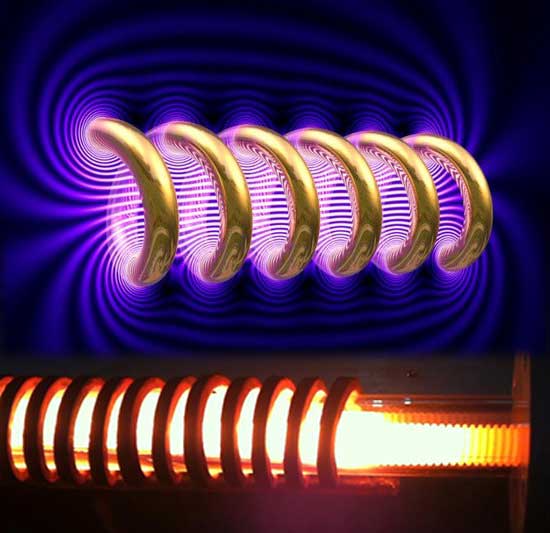

Induction power inverter is the device of convert AC220V / 380V 50/60Hz to DC, then through core technology control(heater card, IGBT, resonant capacitor etc components)covert DC to high frequency AC current.

When the high frequency current connected to a conduct that is curled to cyclic(usually referred to as heating coil, normally copper tube) to generated magnetic field around the coil.

When placed the metal object to this magnetic field, the flux run through it to generated eddy current in the metal object, so that the metal object is heated itself rapidly.

Application for industry

● Induction quenching / hardening

● Induction welding / soldering

● Induction smelting

● Induction annealing / normalizing

● Induction forging

● Shrink fitting

● Induction brazing

● Gear / Shaft quenching industry

● Plumbing sanitary ware industries

Internal structure

Multiple Models for Chosen

Frequency 1-10kHz / 20-50kHz / 30-80kHz / 50-400kHz

Applications

The purpose of induction power generator may be to harden a part to prevent wear; make the metal plastic for forging or hot-forming into a desired shape; braze or solder two parts together; melt and mix the ingredients which go into the high-temperature alloys; or for many number of other heating applications.

Parameters

| Model No. | Input Voltage | Rated Power | Frequency | Weight | Dimensions |

| RZG-15A | 220V±20% | 15KW | 30-80kHz | 25kg | 535*245*550mm |

| RZG-25A | 380V±20% | 25KW | 30-80kHz | 30kg | 535*245*550mm |

| RZG-30AB | 380V±20% | 30KW | 30-80kHz | 35kg / 25kg | 595*275*580mm / 485*275*440mm |

| RZG-40AB | 380V±20% | 40KW | 30-80kHz | 35kg / 25kg | 595*275*580mm / 485*275*450mm |

| RZG-60AB | 380V±20% | 60KW | 30-80kHz | 37kg / 36kg | 650*320*590mm / 485*275*450mm |

| RZG-80AB | 380V±20% | 80KW | 60-80kHz | 54kg / 47kg | 745*345*600mm / 790*425*580mm |

| RZM-15AB | 380V±20% | 15KW | 2-20kHz | 38kg / 33kg | 550*280*540mm / 580*240*520mm |

| RZM-25AB | 380V±20% | 25KW | 2-20kHz | 38kg / 33kg | 550*280*540mm / 580*240*520mm |

| RZM-35AB | 380V±20% | 35KW | 2-20kHz | 38kg / 33kg | 660*330*580mm / 580*240*520mm |

| RZM-45AB | 380V±20% | 45KW | 2-20kHz | 54kg / 43kg | 660*330*580mm / 580*240*520mm |

| RZM-70AB | 380V±20% | 70KW | 2-20kHz | 80kg / 60kg | 430*350*630mm / 580*240*520mm |

| RZM-110AB | 380V±20% | 110KW | 2-20kHz | 100kg / 65kg | 800*420*880mm / 580*400*530mm |

| RZM-160AB | 380V±20% | 160KW | 2-20kHz | 120kg / 75kg | 820*420*880mm / 580*400*530mm |

| RZM-200AB | 380V±20% | 200KW | 2-20kHz | 200kg / 100kg | 780*500*880mm / 580*400*530mm |

| RZC-3 | 220V±20% | 3KW | 200-500kHz | 20kg | 285*287*146mm |

| RZC-6 | 220V±20% | 6KW | 200-500kHz | 23kg | 632*260*550mm |

| RZC-10 | 380V±20% | 10KW | 200-500kHz | 30kg | 630*260*550mm |

| RZC-20 | 380V±20% | 20KW | 200-500kHz | 30kg | 630*260*550mm |

| RZC-30AB | 380V±20% | 30KW | 200-500kHz | 35kg / 25kg | 630*280*535mm / 500*260*450mm |

| RZC-60AB | 380V±20% | 60KW | 200-500kHz | 50kg / 27kg | 750*400*880mm / 500*300*480mm |

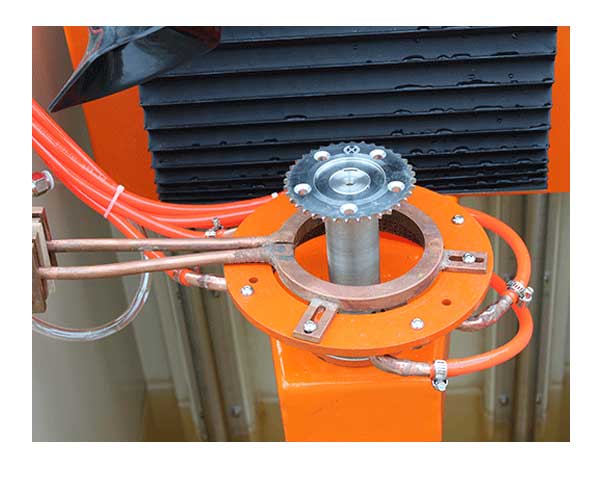

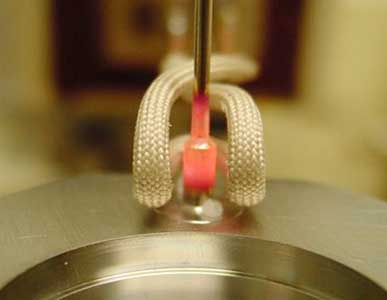

Induction Coil

In the use of the inductoin heating process, success depends to a great degree on proper design of the induction coil.

Induction coil for high frequency induction heating, usually referred to as inductors. normally made by copper tube curled to cyclic.

Inductors vary considerably not only in shape and form but also in size and are usually designed for specific applications or for a family of similar applications.

The inductor designs must follow certain principles of maximum efficiency of heating.

Inductor Types:

Solenoid Coil

Pancake Coil

Channel Coil

Application case

Induction soldering

Shrink fitting

Heat treating

Induction melting

Induction wire annealing

Testing

Ask us for price and solutions today!

Your inquiry will be replied within 24 hours, and we respect your privacy.

Inquiry Form